What are types of PCB?

Printed circuit boards (PCBs) are the heart of all electronic products, but not all are created equal. There are many different types of printed circuit boards made from different materials and manufacturing specifications for a broad range of applications. Since the early 1900s PCBs have evolved considerably and today manufacturers like Unitepcb offer a broad range of circuit board fabrication capabilities, laminate materials, and certifications to meet the quality, precision, and performance demands of the latest technology requirements.

Below is a list of the common types of printed circuit boards.

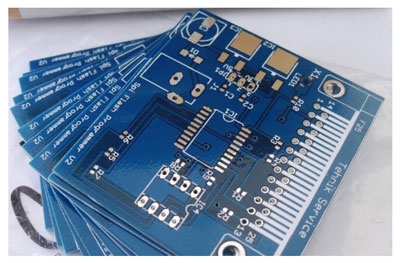

1. Single Sided PCBs

Single-sided PCBs are the basic type of circuit boards, which contain only one layer of substrate or base material. The layer is covered with a thin layer of metal, i.e. Copper- which is a good conductor of electricity. These PCBs also contain a protective solder mask, which is applied on the top of the copper layer along with a silkscreen coat. Some advantages offered by single-sided PCBs are:

• Single-sided PCBs are utilized for volume production and are low in cost.

• These PCBs are utilized for simple circuits such as power sensors, relays, sensors and electronic toys.

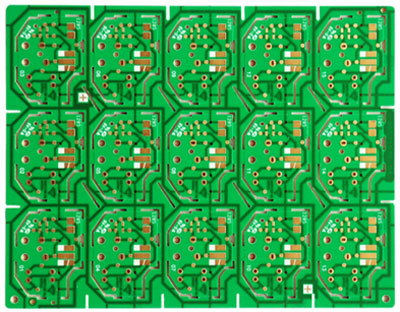

2. Double-sided PCBs

Double-sided PCBs have both sides of the substrate featuring metal conductive layer. Holes in the circuit board allow the metal parts to be attached from one side to the other. These PCBs connect the circuits on the either side by either of the two mounting schemes, namely through-hole technology and surface mount technology. The through-hole technology involves inserting of lead components through the pre-drilled holes on the circuit board, which are soldered to the pads on the opposite sides. The surface mount technology involves electrical components to be directly placed on the surface of the circuit boards. Advantages offered by double sided PCBs are:

• Surface mounting allows more circuits to be attached to the board in comparison to the through-hole mounting.

• These PCBs are utilized in a wide range of applications, including mobile phone system, power monitoring, test equipment, amplifiers, and many others.

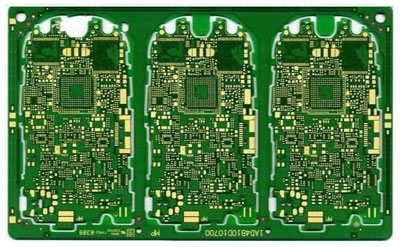

3. Multi-layer PCBs

Multi-layer PCBs are printed circuit boards, which comprise more than two copper layers like 4L, 6L, 8L, etc. These PCBs expand the technology used in double sided PCB’s. Various layers of a substrate board and insulating materials separate the layers in multi-layer PCBs. The PCBs are compact sized, and offer benefits of weight and space. Some advantages offered by multi-layer PCBs are:

• Multi-layer PCBs offer a high level of design flexibility.

• These PCBs play an important role in high speed circuits. They provide more space for conductor pattern and power.

4. Rigid PCBs

Rigid PCBs refer to those types of PCBs whose base material is fabricated from a solid material and which cannot be bent. Some salient advantage offered by them:

• These PCBs are compact, which ensures the creation of variety of complex circuitry around it.

• Rigid PCBs offer easy repair and maintenance, as all the components are clearly marked. Also, the signal paths are well organized.

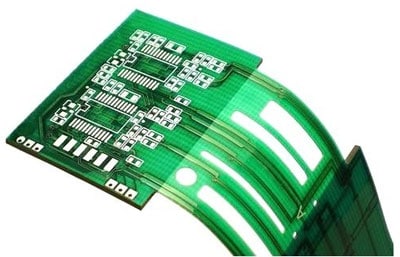

5. Flexible PCBs

Flexible PCBs are constructed on a flexible base material. These PCBs come in single sided, double-sided and multilayer formats. This helps in reducing the complexity within the device assembly. Some advantages offered by these PCBs are:

• These PCBs help save a lot of space, along with reducing the overall board weight.

• Flexible PCBs helps in decreasing the board size, which makes it ideal for various applications where high signal trace density is needed.

• These PCBs are designed for working conditions, where temperature and density is a main concern.

6. Rigid-Flex-PCBs

Rigid flex PCBs are the combination of rigid and flexible circuit boards. They comprise of multiple layers of flexible circuits attached to more than one rigid board.

• These PCBs are precision built. Hence, it is used in various medical and military applications.

• Being light-weight, these PCB offer 60% of weight and space savings.

7. High-Frequency PCBs

High-frequency PCBs are used in the frequency range of 500MHz – 2GHz. These PCBs are used in various frequency critical applications like communication systems, microwave PCBs, microstrip PCBs, etc.

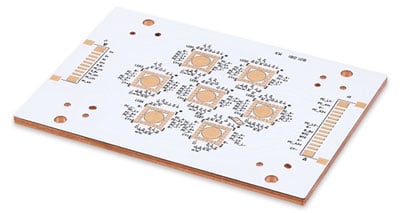

8. Aluminum backed PCBs

These PCBs are used in high power applications, as the aluminum construction helps in heat dissipation. Aluminum backed PCBs are known to offer high level of rigidity and low level of thermal expansion, which makes them ideal for applications having high mechanical tolerance. The PCBs are used for LEDs and power supplies.