Multilayer Aluminum PCB Manufacturing

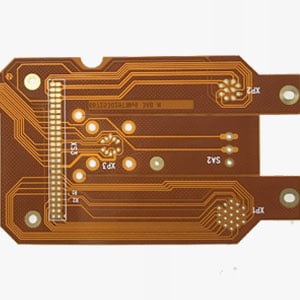

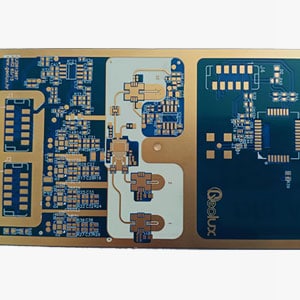

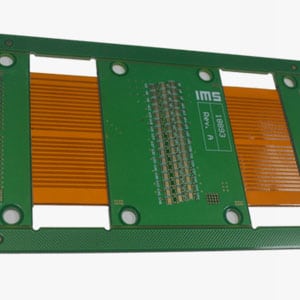

Multilayer aluminum PCBs are made by bonding together multiple layers of aluminum and insulation material using heat and pressure. The process begins by bonding two sheets of aluminum together using an adhesive. A layer of insulating material is then placed between the two sheets of aluminum. The entire assembly is then placed in a press and heated to a high temperature. Once the adhesive has melted, the pressure is released and the sheets are cooled. This process is repeated until all the layers have been bonded together. Finally, the finished PCB is cut to size and drilled to create holes for connecting components. Multilayer aluminum PCBs are used in a variety of electronic devices because they offer excellent heat dissipation and electrical conductivity.

UnitePCB offers advanced multilayer aluminum PCB Manufacturing services. Our high-quality aluminum PCB boards are fabricated using state-of-the-art technology and equipment. We can manufacture any size or shape of aluminum PCB, and we offer a variety of surface finishes to choose from. We also provide one-stop aluminum PCB turnkey assembly services, so you can be sure your boards will be delivered on time and at a competitive price.

Aluminum PCB Classification

Aluminum PCBs are classified according to their laminate material and the type of copper clad. The laminate material is the non-conductive substrate on which the copper circuitry is printed. There are two main types of laminate materials: FR-4 and CEM-1. FR-4 is a glass-reinforced epoxy resin, while CEM-1 is a paper-reinforced thermosetting resin. The type of copper clad refers to the way in which the copper circuitry is bonded to the laminate material.

There are three main types of copper clads bondable, etchable, and rollable. Bondable copper clad is bonded to the laminate material using an adhesive, while etchable copper clad is etched onto the laminate material. Rollable copper clad is bonded to the laminate material using a pressure-sensitive adhesive. Aluminum PCBs are available in a variety of sizes, shapes, and colors. They can be customized to meet the specific needs of any application.

Benefits of Aluminum PCB

1. Improved conductivity and heat dissipation In comparison to ordinary FR4 PCB, aluminum PCB offers superior heat dissipation capabilities. For instance, Fr4 PCB with 1.5mm thickness 1.5mm will have 20-22°C per watt, while an aluminum PCB that has the thickness that is 1.5mm will have an average thermal resistance of between 1 to 2 °C per Watt.

2. There is no serious problem of thermal expansion or contraction. Each substance has its own CTE of thermal expansion. For aluminum, the CTE (22ppm/C) as well as copper (18ppm/C) is very similar. Since aluminum PCBs are efficient in terms of thermal dissipation, they don’t have any significant expansion or contraction problems. They are extremely efficient and robust and reliable.

3. Dimensional Stability: Aluminum PCBs have dimensional stability and steady size. For instance, when heated between 30 to 140 degrees, their size will only change by 2.5%-3.0%.

4. Other: Aluminum PCBs can be utilized in power devices using Surface mount technologies. They are suitable for use in circuit design due to their performance in the area of the expansion of thermal energy in circuit designs. They aid in extending product shelf life as well as products power and density. They are also extremely reliableIn addition, aluminum PCB can help to shrinking the overall volume of the product, they are is also a cheaper option. High dielectric strength and electromagnetic shielding are characteristics of Aluminum materials.

Uses of Aluminum PCB

1. An audio device consists of an input, an output amplifier, a balanced amplifier, an audio amplifier, a preamplifier, and a power amplifier.

2. The power supply includes switching regulators, DC/AC converters, SW regulators, etc.

3. Electronic communication equipment Filtering, High-frequency amplifier appliances, and the circuit for transmitting.

4. Motor drives, etc., for office automation.

5. A car’s electronic regulator, ignition, power supply controller, etc..

6. In a computer, there are components such as the CPU board, the floppy disk drive, and the power supply unit.

7. Modules for power: Inverters, solid-state relays, rectifier bridges.

8. In light of the advocated promotion of energy-saving lamps, a variety of colorful LED lights are well received by the market, and aluminum PCB is also used in LED lights on a massive scale.

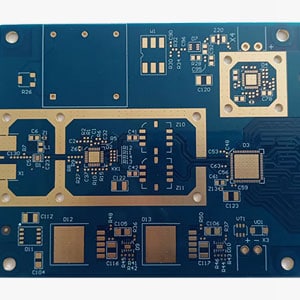

Our Aluminum PCB Manufacturing Capability

As a leading aluminum PCB manufacturer, we have the capabilities to produce high-quality printed circuit boards for a wide range of applications. We use state-of-the-art equipment and processes to ensure that our PCBs meet the highest standards for quality and reliability.

Our state-of-the-art laboratory is equipped with the latest in technology and our team of highly skilled engineers have years of experience in aluminum PCB manufacturing. We are able to provide our clients with the highest quality and most technologically advanced products available on the market today.

In addition to our manufacturing capabilities, we also offer a full suite of design and assembly services. Our turnkey solutions enable us to provide our customers with complete control over their project from start to finish. We are proud to be the partner of choice for many of the world’s leading companies, and we look forward to working with you on your next project.

Video of our PCB products

Video of our PCB production and processing

Why Turn To UnitePCB for Multilayer Aluminum PCBs?

As the demand for smaller, more complex electronics increases, so does the need for printed circuit boards that can accommodate these design requirements. Multilayer aluminum PCBs are an ideal solution for many applications, thanks to their ability to support a high density of components and their excellent thermal conductivity.

At UnitePCB, we have years of experience fabricating high-quality multilayer aluminum PCBs for a wide range of customers. We use state-of-the-art equipment and processes to ensure that our PCBs meet or exceed the highest industry standards. In addition, our team of engineers is available to answer any questions you may have and help you select the best materials and processes for your unique application. Contact us today to learn more about how we can help you with your multilayer aluminum PCB needs.

TECHNICAL SPECIFICATIONS

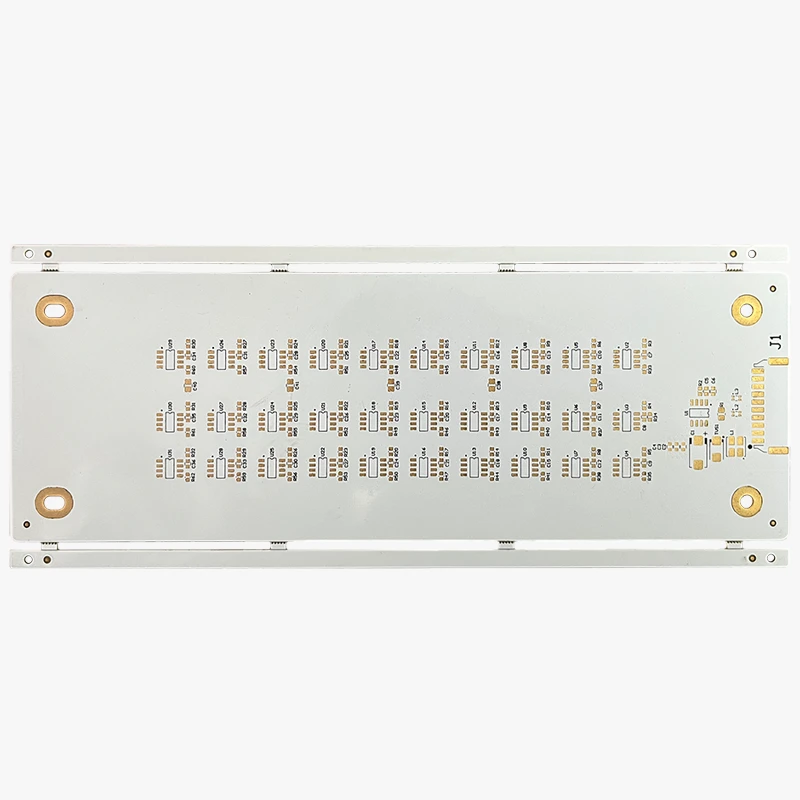

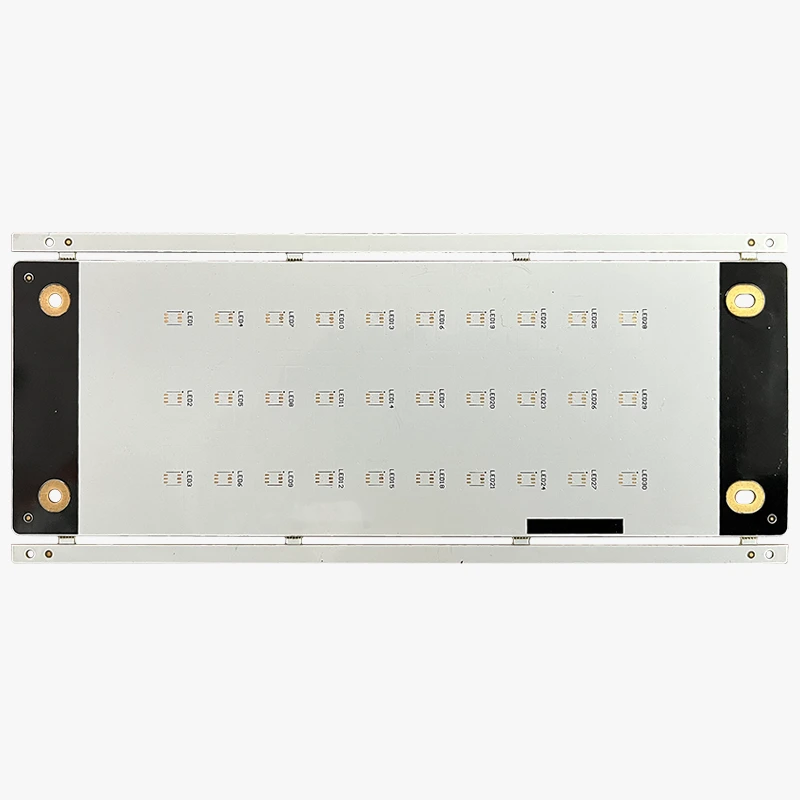

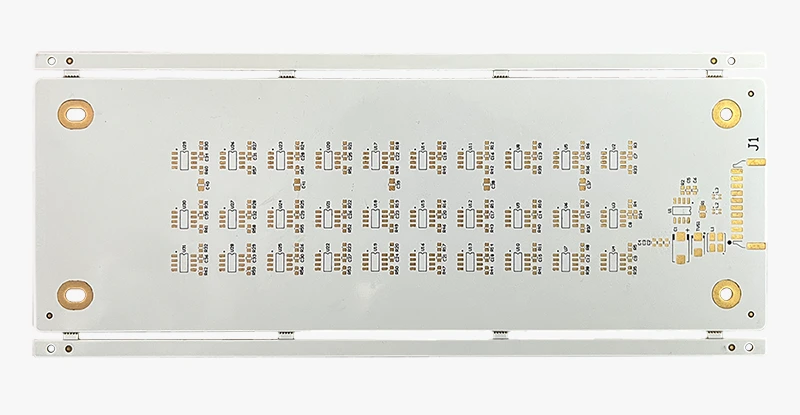

Aluminum PCB multilayer PCB 4-layer PCB MCPCB

| Feature | Parameters |

| Layer Count | 4 layer |

| Material | Aluminum Core Substrate with 4mil Dielectric |

| Dielectric layer thickness | 220UM |

| Thermal Conductivity | 3W/m·K |

| Finished Board Thickness | 2.4mm +/-10% |

| Solder Mask | White x2 |

| Silkscreen | Black x2 |

| Finished Outer Copper Weight | 1oz |

| Surface Finish | ENIG+HASL lead free |

| Copper thickness | 3oz |

| Application | Stage Lamp, High Power Lighting |

| LAYER | 1- 6Layers |

| SUBSTRATE | Aluminium / Copper / Iron Based, TC=1~3W/MK |

| FINAL THICKNESS | 0.02"-0.18"(0.5mm- 4.6mm) |

| SURFACE TREATMENT | Regular Lead: HASL |

| Lead- free | Lead- free HASL, ENG Gold; OSP, Immersion silver |

| MAX/MIN BOARD SIZE | Min: 0.2"x0.2" Max: 43.3"x19" |

| MIN TRACE WIDTH/MIN CLEARANCE | 0.5oz: 4/4mil, 1oz: 5/5mil, 2oz: 5/7mil, 3oz: 7/8mil,4oz: 10/10mil |

| MIN HOLE RING | 0.5oz: 4mil, 1oz: 5mil, 2oz: 7mil, 3oz: 10mil, 4oz: 16mil |

| COPPER THICKNESS | 0.5oz- 4oz |

| MIN HOLE SIZE AND TOLERANCE | Min hole: 30mil (Final Thickness 0.5mm- 2.0mm) 45mil (Final Thickness 2.0mm- 4.6mm) |

| Tolerance | PTH±4mil, NPTH±3mil |