Comprehensive Introduction of Ceramic PCB Substrate Products

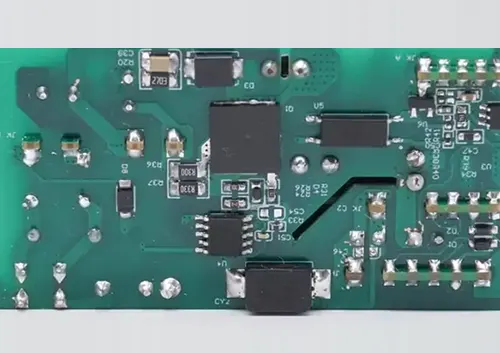

Ceramic PCBs are typically used in applications requiring high performance. Military applications, space program components, high-power laser applications, and so on. However, as manufacturing processes improve and costs fall, they are making inroads into general industry applications that require higher thermal performance.

This article will provide a thorough overview of ceramic PCBs, including their characteristics, classifications, benefits and drawbacks, and applications.

What Is the Ceramic Substrate?

Ceramic PCBs have 10 to 100 times more heat transfer properties than metal core PCBs, as well as good high-frequency performance and electrical properties.

The ultra-thin composite substrate has excellent electrical insulation performance, high thermal conductivity, excellent soft brazing property, and high adhesion strength, and can etch all types of graphics like a PCB board, while also having a high current carrying capacity. As a result, the ceramic substrate has become the fundamental material of high-power electronic circuit structure and interconnection technology.

Types of Ceramic PCBs

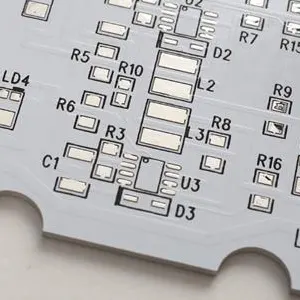

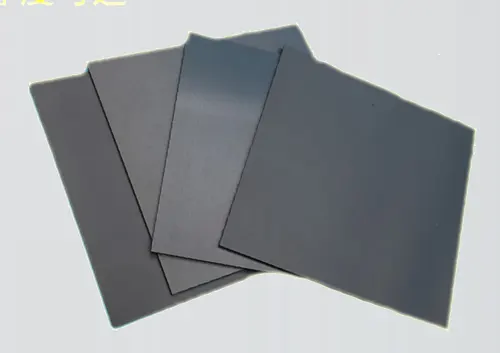

Ceramic PCBs include aluminum, AlN, BeO, Si₃N₄, hybrid substrate boards, and other substrates. There are three types of circuit board layers: single-layer, double-layer, and multilayer. Only the ceramic PCB types based on the various ceramic substrates are listed here.

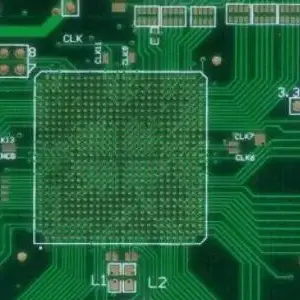

Alumina PCB

Aluminum oxide (Al₂O₃) PCB, also known as alumina PCB, is the most commonly used ceramic PCB in the market today due to its low cost and good properties. Alumina has excellent thermal conductivity as well as electrical resistance. As a result, there is no need for an insulation layer when using alumina PCB.

There are 75%, 96%, and 99% alumina PCBs on the market. The higher the purity, the better the properties, but also the higher the cost. If your devices do not require a lot of power, an alumina PCB will suffice.

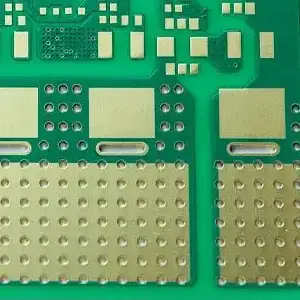

Aluminum Nitride PCB

Aluminum nitride PCBs are the most promising ceramic PCBs for the future. Using them, thermal energy is immediately dissipated from ICs and other expensive components. As a result, AlN PCBs are used as base plates in high-power devices such as LED ship lights, truck lamps, solar battery modules, large-scale integrated circuits, and so on. Thermal does not accumulate in their chips, allowing the devices to operate properly at high currents and for extended periods of time.

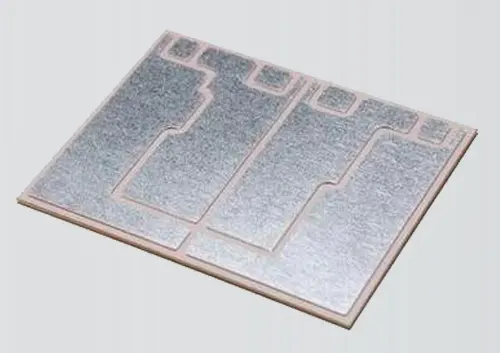

Silicon Nitride PCB

Unlike fragile traditional ceramic materials, silicon nitride PCBs or Si₃N₄ PCBs have good mechanical strength and fracture toughness at high temperatures. Furthermore, Si₃N₄ PCBs have a high thermal conductivity (80+ W/MK). Furthermore, silicon nitride PCBs have the same thermal expansion coefficient as Si.

IGBT modules for vehicles, as you know, require much higher thermal conductivity than industrial class IGBTs. And vehicle modules operate in high-vibration environments. Car materials should be impact resistant in order to be safe.

Silicon Carbide PCB

Silicon carbon (SiC) is actually diamond, but the carbon ratios are different. As a result, silicon carbide printed circuit boards have an extremely high thermal resistance. SiC PCBs can easily operate at 1000°C. As a result, they can be used in laser fields.

SiC has the property Si, so it has semiconductor-like properties. In other words, a SiC PCB lacks high insulation compared to other ceramic PCBs.

Advantages of Ceramic Printed Circuit Boards

Due to its numerous benefits, a ceramic PCB is regarded as the best option for a variety of applications. Here are some of the benefits that make ceramic PCBs a popular choice.

● High Thermal Expansion: Ceramic printed circuit boards have a high thermal coefficient of expansion. Ceramic PCBs have a high thermal conductivity even at high temperatures, making them an excellent choice for a wide range of devices.

● High Pressure: Ceramic PCBs are extremely adaptable and can function successfully even when subjected to extreme pressure. Ceramic circuit boards are ideal for high-performance applications.

● High Insulation: Because ceramic is extremely insulating, heat will be less likely to pass through the substrate, protecting the circuit board’s components from damage.

● High Temperature: Ceramic remains workable even in extreme weather and temperature, providing increased durability and dependability in a variety of industries.

● High Frequency: Ceramic has a high frequency and can be used in industries such as aerospace and medicine that require high-frequency data and electrical signal transmission.

● Cost Efficient: Ceramic PCBs improve performance while lowering fabrication and design complexity. As a result, ceramic boards are less expensive than metal (Cu/AL) core PCBs.

Disadvantages of Ceramic Circuit Board

● Fragile: this is the main disadvantage, as it can only make a small area of the circuit board.

● Expensive: There are increasing demands for electronic products. Ceramic circuit boards can only meet the needs of high-end products, and low-end products will be avoided entirely.

Uses of Ceramic PCB

A ceramic PCB made of ceramic is a type of metal core PCB. While other circuit boards, such as FR4 or aluminum, can be used for electrical equipment, ceramic circuit boards provide an extra layer of protection. The PCB also protects the devices from harm. Ceramic board is commonly used in the following applications:

● Spotlights and LEDs with high current

● Power controllers

● Exchange converters

● Optical systems with variable aperture

● Automobile power regulators

● Industrial power tools

● Semiconductor cooling devices

● Integrated circuit arrays

● Printers

● Amplifiers for audio

● Substrates for solar cells

● Transistors with high power and transistor arrays

● Electrical applications

Final Words

Overall, ceramic PCBs have a wide range of applications due to their high thermal conductivity, low CTE, and low dielectric constant. When selecting a ceramic circuit board manufacturer, make sure that the builder has superior processing capabilities. To achieve maximum thermal conductivity and temperature resistance, oxidation must be controlled.